Access Energy Cooperative recently issued the following announcement.

Anaerobic digestion (AD) is the process of converting biodegradable organic materials — such as manure — into biogas, a renewable energy source. AD also produces a residual effluent (digestate) that can be used as a soil conditioner.

System approaches

There are two main approaches to anaerobic digestion — conventional and high-solids. Conventional AD manages organic matter in mostly liquid form with a total solids (TS) concentration of up to 10% to 12%. This approach is accomplished using one of three types of AD equipment:

- Completely mixed digesters

- Covered lagoons

- Plug flow digesters

The conversion process

The conversion process requires both a biological process and a mechanical process to work together. The biological process involves complex chemistry, but the there are six key parameters that determine the efficiency of converting organic materials to biogas.

1. Retention time. Solids retention time (SRT) is the average length of time the feedstock volatile solids (VS) remains in the digester’s reactor and remain in contact with the microbes. Typical SRT for conventional AD is in the range of five to 30 days, depending on the temperature.

2. Organic loading rate (OLR). OLR is the amount of VS that can be fed into the digester. The units of OLR are typically pounds of VS added per thousand cubic feet of digester volume per day. ORL is typically in the range of 100 to 600 pounds per 1,000 cubic feet.

3. Operating temperature. Ambient conditions are generally used for covered lagoons in warm climates. Conventional AD systems are commonly designed to operate in either the mesophilic (86°F to 104°F) or thermophilic (122°F to 140°F) temperature range.

4. Characteristics of volatile solids. Manure solids are composed of VS and minerals. VS refers to the fraction of TS that are combustible and are used as an estimate of organic matter content.

5. Inhibitors. These are toxic chemicals or contaminants or other conditions that prohibit the controlled biological process. Inhibitors include cleaning and sanitation chemicals like chlorine and ammonia. Very small amounts are acceptable, even beneficial, but excess amounts are toxic.

6. Carbon to nitrogen (C/N) ratio. The optimum C/N ratio of feedstock for anaerobic bio-digestion is between 20 and 30 to 1. Any higher and ancillary bacteria will quickly exhaust the available nitrogen, leaving none for AD bacteria and reducing gas production. If it's too low, the overabundance of nitrogen forms ammonium ions that increases the alkalinity and reduces gas production.

System yields

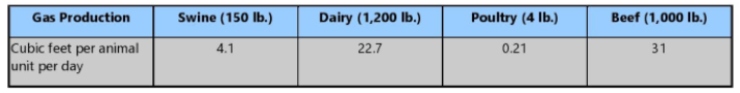

What is the typical yield of methane from anaerobic digestion? According to the University of Missouri Extension program, methane yield is generally 8 to 15 cubic feet per pound of VS. The volume in cubic by type of livestock is shown in the following table.

Consider all of these parameters when you're planning your AD system to optimize performance. See the Anaerobic Digester/Biogas System Operator Guidebook from the U.S. Environmental Protection Agency for more information.

Original source can be found here.

Alerts Sign-up

Alerts Sign-up